Page 22 - Welder - TT - Kannada

P. 22

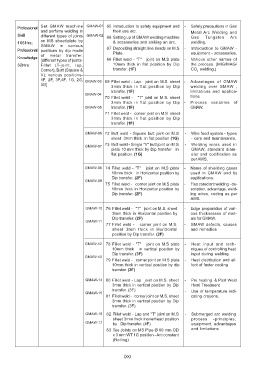

Professional Set GMAW machine GMAW-01 65 Introduction to safety equipment and - Safety precautions in Gas

and perform welding in their use etc. Metal Arc Welding and

Skill different types of joints GMAW-02 66 Setting up of GMAW welding machine Gas Tungsten Arc

on MS sheet/plate by

166Hrs; & accessories and striking an arc. welding.

GMAW in various

Professional positions by dip mode 67 Depositing straight line beads on M.S - Introduction to GMAW -

of metal transfer. Plate. equipment - accessories.

Knowledge 68 Fillet weld - "T" joint on M.S plate - Various other names of

[different types of joints-

32Hrs Fillet (T-joint, lap, 10mm thick in flat position by Dip the process. (MIG/MAG/

Corner), Butt (Square & transfer. (1F) CO welding.)

2

V); various positions-

1F, 2F, 3F,4F, 1G, 2G, GMAW-03 69 Fillet weld - Lap joint on M.S. sheet - Advantages of GMAW

3G] 3mm thick in flat position by Dip welding over SMAW ,

transfer. (1F) limitations and applica-

GMAW-04 tions

70 Fillet weld - "T" joint on M.S. sheet

3mm thick in flat position by Dip - Process variables of

GMAW-05 transfer. (1F) GMAW.

71 Fillet weld - corner joint on M.S. sheet

3mm thick in flat position by Dip

transfer. (1F)

GMAW-06 72 Butt weld - Square butt joint on M.S - Wire feed system - types

sheet 3mm thick in flat position (1G) - care and maintenance.

GMAW-07 73 Butt weld - Single "V" butt joint on M.S - Welding wires used in

plate 10 mm thick by Dip transfer in GMAW, standard diam-

flat position. (1G) eter and codification as

per AWS.

GMAW-08 74 Fillet weld - "T" joint on M.S plate - Name of shielding gases

10mm thick in Horizontal position by used in GMAW and its

Dip transfer. (2F) applications.

GMAW-09

75 Fillet weld - corner joint on M.S plate - Flux cored arc welding - de-

10mm thick in Horizontal position by scription, advantage, weld-

Dip transfer. (2F) ing wires, coding as per

AWS.

GMAW-10 76 Fillet weld - "T" joint on M.S. sheet - Edge preparation of vari-

3mm thick in Horizontal position by ous thicknesses of met-

Dip transfer. (2F) als for GMAW.

GMAW-11

77 Fillet weld - corner joint on M.S. - GMAW defects, causes

sheet 3mm thick in Horizontal and remedies

position by Dip transfer. (2F)

GMAW-12 78 Fillet weld - "T" joint on M.S plate - Heat input and tech-

10mm thick in vertical position by niques of controlling heat

Dip transfer. (3F) input during welding.

GMAW-13

79 Fillet weld - corner joint on M.S plate - Heat distribution and ef-

10mm thick in vertical position by dip fect of faster cooling

transfer. (3F)

GMAW-14 80 Fillet weld - Lap joint on M.S. sheet - Pre heating & Post Weld

3mm thick in vertical position by Dip Heat Treatment

transfer. (3F) - Use of temperature indi-

GMAW-15

81 Fillet weld - corner joint on M.S. sheet cating crayons.

3mm thick in vertical position by Dip

transfer. (3F)

GMAW-16 82 Fillet weld - Lap and "T" joint on M.S - Submerged arc welding

sheet 3mm thick inoverhead position process -principles,

GMAW-17 by Dip transfer. (4F) equipment, advantages

83 Tee Joints on MS Pipe Ø 60 mm OD and limitations

x 3 mm WT 1G position - Arc constant

(Rolling)

(xx)