Page 15 - Welder - TT - Kannada

P. 15

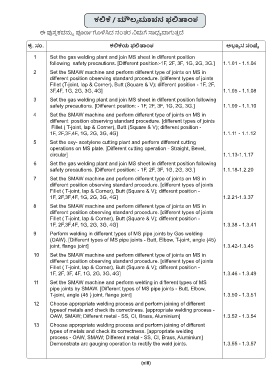

ಕ್ಲ್ಕೆ / ಮೌಲ್್ಯ ಮ್ಪನ ಫಲ್ತಾಾಂಶ

ಈ ಪುಸ್ತು ಕ್ವನು್ನ ಪೂಣ್ಡಿಗೊಳಿಸ್ದ್ ನಂತರ ನಿಮಗೆ ಸಾಧ್ಯಾ ವಾಗುತತು ದೆ

ಕ್್ರ . ಸಂ. ಕ್ಲ್ಕೆಯ ಫಲ್ತಾಾಂಶ ಅಭಾ್ಯ ಸ ಸಂಖ್್ಯ

1 Set the gas welding plant and join MS sheet in different position

following safety precautions. [Different position:-1F, 2F, 3F, 1G, 2G, 3G.] 1.1.01 - 1.1.04

2 Set the SMAW machine and perform different type of joints on MS in

different position observing standard procedure. [different types of joints

Fillet (T-joint, lap & Corner), Butt (Square & V); different position - 1F, 2F,

3F,4F, 1G, 2G, 3G, 4G] 1.1.05 - 1.1.08

3 Set the gas welding plant and join MS sheet in different position following

safety precautions. [Different position: - 1F, 2F, 3F, 1G, 2G, 3G.] 1.1.09 - 1.1.10

4 Set the SMAW machine and perform different type of joints on MS in

different position observing standard procedure. [different types of joints

Fillet ( T-joint, lap & Corner), Butt (Square & V); different position -

1F, 2F,3F,4F, 1G, 2G, 3G, 4G] 1.1.11 - 1.1.12

5 Set the oxy- acetylene cutting plant and perform different cutting

operations on MS plate. [Different cutting operation - Straight, Bevel,

circular] 1.1.13-1.1.17

6 Set the gas welding plant and join MS sheet in different position following

safety precautions. [Different position: - 1F, 2F, 3F, 1G, 2G, 3G.] 1.1.18-1.2.20

7 Set the SMAW machine and perform different type of joints on MS in

different position observing standard procedure. [different types of joints

Fillet ( T-joint, lap & Corner), Butt (Square & V); different position -

1F, 2F,3F,4F, 1G, 2G, 3G, 4G] 1.2.21-1.3.37

8 Set the SMAW machine and perform different type of joints on MS in

different position observing standard procedure. [different types of joints

Fillet ( T-joint, lap & Corner), Butt (Square & V); different position -

1F, 2F,3F,4F, 1G, 2G, 3G, 4G] 1.3.38 - 1.3.41

9 Perform welding in different types of MS pipe joints by Gas welding

(OAW). [Different types of MS pipe joints - Butt, Elbow, T-joint, angle (45)

joint, flange joint] 1.3.42-1.3.45

10 Set the SMAW machine and perform different type of joints on MS in

different position observing standard procedure. [different types of joints

Fillet ( T-joint, lap & Corner), Butt (Square & V); different position -

1F, 2F, 3F, 4F, 1G, 2G, 3G, 4G] 1.3.46 - 1.3.49

11 Set the SMAW machine and perform welding in different types of MS

pipe joints by SMAW. [Different types of MS pipe joints - Butt, Elbow,

T-joint, angle (45 ) joint, flange joint] 1.3.50 - 1.3.51

12 Choose appropriate welding process and perform joining of different

typesof metals and check its correctness. [appropriate welding process -

OAW, SMAW; Different metal - SS, CI, Brass, Aluminium] 1.3.52 - 1.3.54

13 Choose appropriate welding process and perform joining of different

types of metals and check its correctness. [appropriate welding

process - OAW, SMAW; Different metal - SS, CI, Brass, Aluminium]

Demonstrate arc gauging operation to rectify the weld joints. 1.3.55 - 1.3.57

(xiii)