Page 19 - TDM - 1st Year - TP - Hindi

P. 19

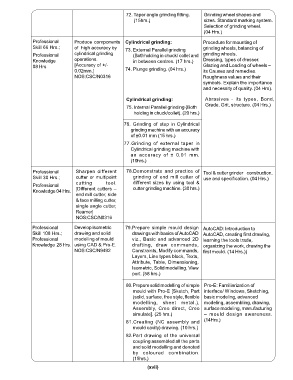

72. Taper angle grinding fitting. Grinding wheel shapes and

(15hrs.) sizes. Standard marking system.

Selection of grinding wheel.

(04 Hrs.)

Professional Produce components Cylindrical grinding: Procedure for mounting of

Skill 66 Hrs.; of high accuracy by 73. External Parallel grinding grinding wheels, balancing of

Professional cylindrical grinding (Bothholding in chuck/ collet and grinding wheels.

Knowledge operations. in between centres. (17 hrs.) Dressing, types of dresser.

08 Hrs [Accuracy of +/- Glazing and Loading of wheels –

0.02mm.] 74. Plunge grinding. (04 hrs.) its Causes and remedies.

NOS:CSC/N0316 Roughness values and their

symbols. Explain the importance

and necessity of quality. (04 Hrs).

Cylindrical grinding: Abrasives - its types, Bond,

Grade, Grit, structure. (04 Hrs.)

75. Internal Parallel grinding (Both

holding in chuck/collet). (20 hrs.)

76. Grinding of step in Cylindrical

grinding machine with an accuracy

of ±0.01 mm (15 hrs.)

77.Grinding of external taper in

Cylindrical grinding machine with

an accuracy of ± 0.01 mm.

(10hrs.)

Professional Sharpen different 78.Demonstrate and practice of Tool & cutter grinder construction,

Skill 30 Hrs.; cutter or multipoint grinding of end mill cutter of use and specification. (04 Hrs.)

cutting tool. different sizes by using tool &

Professional cutter grinding machine. (30 hrs.)

Knowledge 04 Hrs. [Different cutters –

end mill cutter, side

& face milling cutter,

single angle cutter,

Reamer]

NOS:CSC/N0316

Professional Develop isometric 79.Prepare simple mould design AutoCAD: Introduction to

Skill 108 Hrs.; drawing and solid drawings with basics of AutoCAD AutoCAD, creating first drawing,

Professional modelling of mould viz., Basic and advanced 2D learning the tools trade,

Knowledge 28 Hrs. using CAD & Pro-E. drafting, draw commands, organizing the work, drawing the

NOS:CSC/N9492 Constraints, Modify commands, first mould. (14 Hrs.))

Layers, Line types block, Texts,

Attribute, Table, Dimensioning,

Isometric, Solid modelling, View

port. (58 hrs.)

80.Prepare solid modelling of simple Pro-E: Familiarization of

mould with Pro-E [Sketch, Part interface/ Windows, Sketching,

(solid, surface, free style, flexible basic modeling, advanced

modelling, sheet metal.), modeling, assembling, drawing,

Assembly, Creo direct, Creo surface modeling, manufacturing

simulate]. (25 hrs.) – mould design awareness.

81.Creating (NC assembly and (14Hrs.)

mould cavity) drawing. (10 hrs.)

82.Part drawing of the universal

coupling assembled all the parts

and solid modelling and denoted

by coloured combination.

(15hrs.)

(xvii)