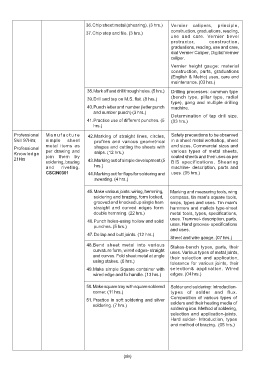

Page 16 - Fitter 1st Year - TT - Hindi

P. 16

36.Chip sheet metal (shearing). (3 hrs.) Vernier calipers, principle,

construction, graduations, reading,

37.Chip step and file. (3 hrs.)

use and care. Vernier bevel

protractor, construction,

graduations, reading, use and care,

dial Vernier Caliper, Digital Vernier

caliper.

Vernier height gauge: material

construction, parts, graduations

(English & Metric) uses, care and

maintenance. (03 hrs.)

38.Mark off and drill through holes. (5 hrs.) Drilling processes: common type

(bench type, pillar type, radial

39.Drill and tap on M.S. flat. (8 hrs.)

type), gang and multiple drilling

40.Punch letter and number (letter punch machine.

and number punch) (3 hrs.)

Determination of tap drill size.

41.Practice use of different punches. (5 (03 hrs.)

hrs.)

Professional Manufacture 42.Marking of straight lines, circles, Safety precautions to be observed

Skill 97Hrs; simple sheet profiles and various geometrical in a sheet metal workshop, sheet

metal items as and sizes, Commercial sizes and

Professional per drawing and shapes and cutting the sheets with various types of metal sheets,

Knowledge join them by snips. (12 hrs.) coated sheets and their uses as per

21Hrs 43.Marking out of simple development (5

soldering, brazing BIS specifications. Shearing

and riveting. hrs.) machine- description, parts and

CSC/N0301 44.Marking out for flaps for soldering and uses. (05 hrs.)

sweating. (4 hrs.)

45.Make various joints: wiring, hemming, Marking and measuring tools, wing

soldering and brazing, form locked, compass, tin man's square tools,

grooved and knocked up single hem snips, types and uses. Tin man's

straight and curved edges form hammers and mallets type-sheet

double hemming. (22 hrs.) metal tools, types, specifications,

uses. Trammel- description, parts,

46.Punch holes-using hollow and solid

punches. (5 hrs.) uses. Hand grooves- specifications

and uses.

47.Do lap and butt joints. (12 hrs.)

Sheet and wire gauge. (07 hrs.)

48.Bend sheet metal into various Stakes-bench types, parts, their

curvature form, wired edges- straight uses. Various types of metal joints,

and curves. Fold sheet metal at angle their selection and application,

using stakes. (6 hrs.)

tolerance for various joints, their

49.Make simple Square container with selection& application. Wired

wired edge and fix handle. (13 hrs.) edges. (04 hrs.)

50.Make square tray with square soldered Solder and soldering: Introduction-

corner. (11 hrs.) types of solder and flux.

Composition of various types of

51.Practice in soft soldering and silver

soldering. (7 hrs.) solders and their heating media of

soldering iron. Method of soldering,

selection and application-joints.

Hard solder- Introduction, types

and method of brazing. (05 hrs.)

(xiv)